Have you ever asked yourself exactly how steel structures are made? The process is both complex as well as specific. The manufacture of a steel structure is an outstanding combination of engineering, draftsmanship, ingenuity, teamwork, know-how and steel building production expertise. Each building receives the utmost care and also interest throughout the production procedure, made by skilled artisans and monitored by a specialized staff of specialists from beginning to end. Precision design, machinery as well as elements plus outstanding quality assurance generate a precision premium quality manufactured item.

When a customer has actually purchased a pre-engineered steel structure or steel structure system, their sales individual, that carries out multiple functions of structure professional, building designer, professional and also estimator, forwards the buyer’s order to the steel structure factory. In the top metal structure factories, the factory itself fabricates all needed building parts in residence. That way, all components work and fit quickly at work website with no shocks and no awaiting parts to get here from various suppliers.

At the steel building factory, the order entrance division supervises the order from start to finish, from the time the order is gotten up until the steel building is shipped. Steel structure factory personnel confirms all design codes, snow as well as wind loads and seismic info to make certain that everything adhere to the purchaser’s contract as well as goes into the order right into scheduling software application to guarantee that the structures make is effectively taken care of.

Pre-engineered steel structures engineers are responsible for optimization of the steel building, each engineer accredited by the state where the building will be constructed. Structure details consisting of snow as well as wind lots as well as seismic information is input into a sophisticated steel building software application that generates engineered store drawings for the framework of the structure as well as other illustrations required for the buildings manufacture and also construction.

The metal structure factory’s pre-engineered steel building designers assess the structure drawings and inspect the purchase order once more for precision. Permit illustrations are created that can be made use of to aid safeguard permits to set up the structure.

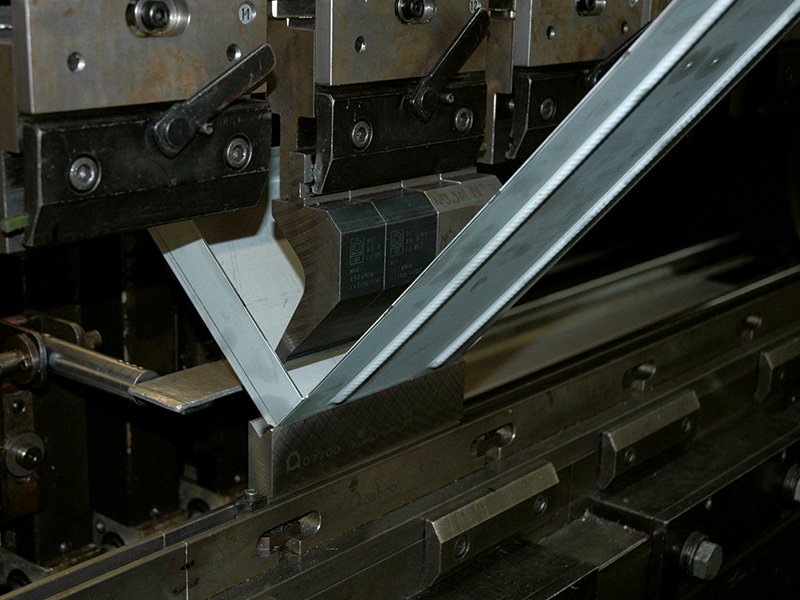

Real building production starts with the input of building specs into CNC (Computer Numerical Control) equipment, a procedure that involves making use of computer systems to control devices configured with CNC machining language (G-code). The CNC machinery manages all maker attributes including feeds as well as speeds up.

Elements of steel structures, such as I-beams, gutters as well as down spouts, sidewalls and also end wall panels, as well as also standing joint roofings are methodically produced in marked areas called “lines” throughout the metal building factory. Each manufacturing line finishes a particular function, automated by utilize of conveyors that relocate the steel sheet, I-beams as well as made steel components from station to station. Since each steel structure is produced to purchase, building elements are produced as called for to satisfy each steel structures specific requirements.

The manufacture of steel buildings rafters as well as columns begins with the Plasma Table. The Plasma Table cuts the web, the center of the rafter or column (like the facility of the letter “H”). The internet relocates to a holding terminal waiting to relocate by automated conveyor to the terminal where the internet will be tack-welded to the flange.

The flange machine cuts flanges into specified sizes identified by the requirements of the pre-engineered building from steel bar stock. After cutting, the flanges relocate to a holding terminal waiting to move by automated conveyor to the station where the flanges will be tack-welded to the web prior to going through the automated welding device.

For more information, visit Elemet MFG, where we discuss various subjects such as metal manufacturing.